REBUILD PROCESS

-

ANALYSIS

Rosier Racing will perform a full analysis of the car/engine before we assume the worst. This could end up saving the customer a huge amount of money if the engine does not necessarily need rebuilding and there is a different issue present. Methods we use for analysis include leakage testers, borescoping, compression tester and exhaust gas tested to name a few.

-

TEARDOWN

Should we discover something nasty or terminal with the engine we will take the engine out of the car and then start to strip it down - documenting the process as we go. Each engine is stored on its own labelled trolley and kept together for the entirety of it’s build, with an engine ‘passport’ that moves around with it.

-

CLEAN/INSPECTION

Once the engine is fully stripped it goes into the washroom, the entire engine is cleaned in one go by the same person. Cleaning is the best time to inspect the engine components to determine if there is any further damage that cannot be seen when the parts are dirty. A list of options will be provided to the customer on how to proceed. Every job is slightly different so a bespoke feedback is given to each customer.

-

MEASURE

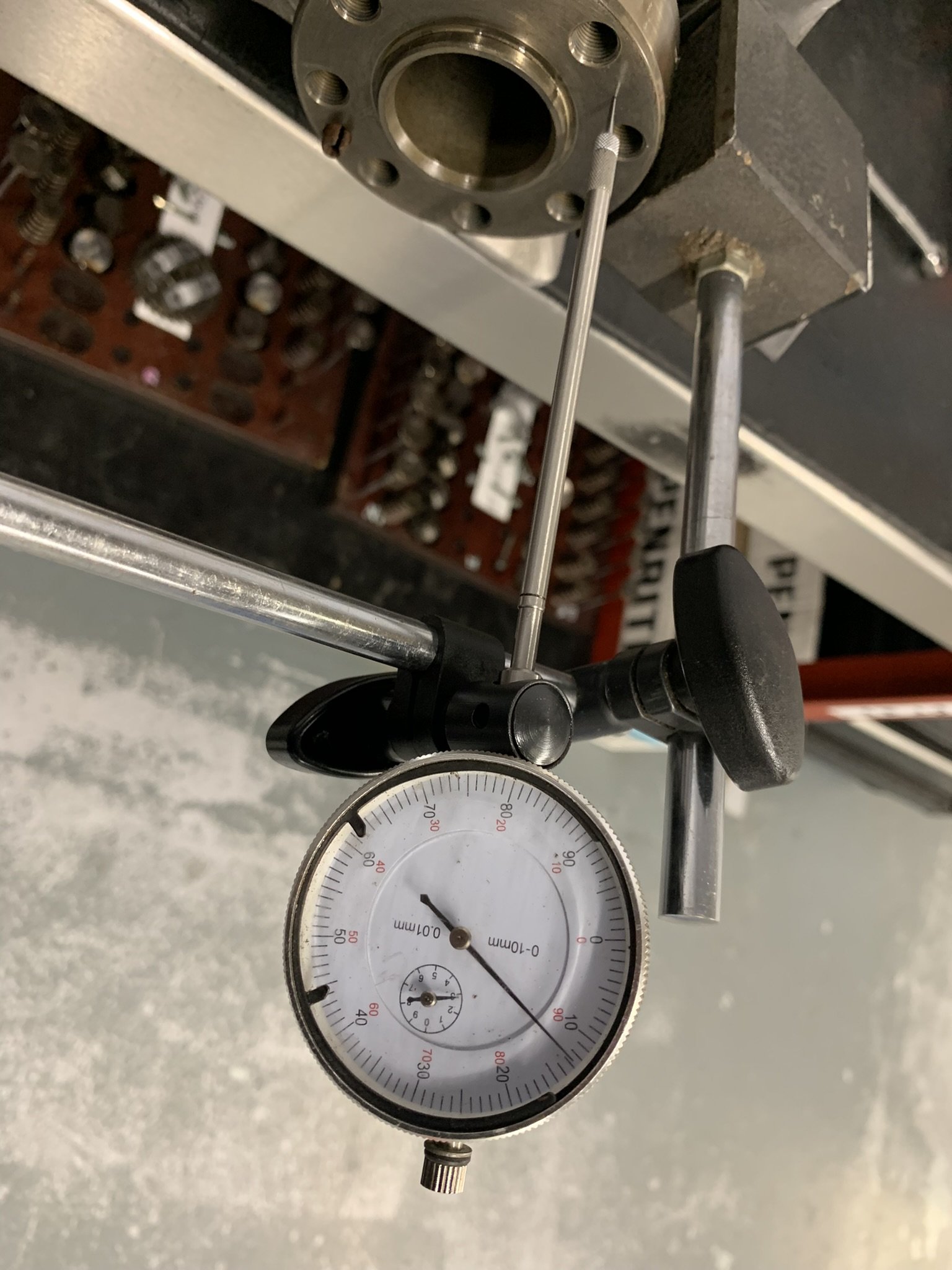

Once clean, every component that needs measuring is measured. It is crucial that every component is within the manufactures recommended guidelines for rebuild otherwise the component needs to be replaced. We stock a large amount of these second hand components to keep costs down to customers. In cases where we don’t stock these parts, the customer is informed before ordering new components.

-

REBUILD

A deposit is paid, parts are ordered and when they are all in stock the rebuild process begins. If the engine requires machining this is done before the rebuild process begins, parts that have been machined go back to the clean/inspection process and are re-measured before assembly. The build takes place in a clean engine build specific workshop away from dust and noise produced by a normal car garage. Up-most care is taken with every component in an F1 style environment. Our engine builders have previous F1/INDYCAR build shop experience and treat your cars with the same precision and respect.

-

TEST/SIGN OFF

In some cases (engine specific) engine dyno services are offered as a method to test and ‘run-in’ the engine. For engines we cannot dyno, we re-install them to the car and then take them on several test drives. Before the car goes on any test drives it is fully warmed up, systems bled and leak checked. We use coolant pressure testing systems to ensure every install is completely leak free. Once we are certain the build and install are perfect then we inform the customer the car is ready for collection. No build leaves our workshop until we are 100% satisfied that we have done the best job we can.